Laboratories

Regulations on educational laboratory D-7

Regulations on educational laboratory D-27

Regulations on educational laboratory D-111

Regulations on educational and scientific laboratory D-113

Regulations on educational laboratory D-125

At the department of milk technology, oil and fat products and the beauty industry for scientific and teaching staff and students use the following rooms:

office of the head of the department |

D-104 |

teaching |

D-101 |

teaching |

D-105 |

The department has the necessary area and material base for the training of specialists: chemical laboratory, an audience for conducting practical classes and consultations on course and diploma design, laboratory of milk technology, fat technology laboratory, research laboratory.

At the department of milk technology, oil and fat products and the beauty industry have such premises for conducting classes with students: educational laboratories D-7, D-27, D-111, D-125; postgraduate D-1; lecture hall D-5; lecture hall A-422, D-113 – the research and production laboratory "Quality and safety control of food products" was created with the assistance of the Erasmus+ program Capacity Building "Ag-Lab".

Various modern devices are used during classes.

Milk analyzer “Lactan-1”

This equipment is widely used by veterinarians and dairy specialists for temperature determination, mass fraction of fat, squirrel, dry skimmed milk residue, of added water and density in the whole fresh sample, canned, pasteurized, normalized, skimmed milk and long-term storage milk.

“Lactan 1-4” – it is reliable, high-quality analyzer that is easy to use and stable in operation, which allows to reduce the material and time costs for the analysis.

Apparatus for melting cheese mass.

Produced by order of the department for research and development of new technological instructions and formulations of fused(processed) cheeses. Used for grinding, mix, melting and cooling of cheese mass. Melting can be carried out under vacuum or without it. The device is a cylindrical bowl with an elliptical bottom, that has a steam shirt, thermal insulation and outer metal casing. The mixer is driven by a three-speed electric motor. At the end of the output shaft, a stirring device of a welded structure made of stainless steel strips is attached. The crushed cheese mass is loaded into the boiler, it is hermetically closed with a lid, turn on the stirring device and supply hot water to the heat exchange jacket. The curd mass is heated to 85…90 °C. Melting is carried out by stirring the curd mass for 15…18 min.

Intermittent oil maker.

Produced by order of the department for research and development of new technological instructions and recipes of butter. The drum-type periodic butter maker is intended for whipping cream, previously obtained by separation in a separator, in butter. Fatty cream from 25 to 40 percent are poured through the hatch into the drum of the oil maker, approximately until 0,4-0,5 (to half) of the entire geometric volume. Duration of whipping from 40 minutes to 120 minutes and depends on the temperature, composition of raw materials, degree of pasteurization. There are blades inside the drum, which pick up the cream and fall under its own weight, are broken in the drum. Repeated impacting and mixing lead to oil compaction, because of which a product of plastic consistency is formed. The drum stops after the formation of an oil grain, then the chips are drained into the flask through the drain valve. Oil grains are whipped until then, until a continuous layer of oil is formed. Structurally, the oil maker consists of a cylindrical horizontal container (drum), which is installed on the frame. There are four special blades inside the container, placed at a certain angle. The gear motor is also mounted on the frame, through a coupling connection with the tank. With its help, the container is rotated around its axis. The container is equipped with a hatch for loading cream, as well as a crane for draining chips.

The cheese bath was made to the order of the department.

The curd bath is used in the dairy industry and is designed to heat milk to the temperature of adding leaven, milk fermentation, formation and cooling of curd, production and drying of cheese grain.

The bathtub has an oval-shaped body, heat exchange shirt. The flat bottom allows you to increase the heat exchange surface and improve the heating of the product. In the process of making cheese, manual lyres are used to cut the curd. On one side, the tub has a connection for releasing cheese. On the other side, on top, there is a connection for draining water from the heat exchange jacket and a connection for water when filling the heat exchange jacket. The cheese bath has a removable lid. Cheese baths are a mandatory element of the traditional cheese production line.

Centrifuge SM-3.01 micromed

Periodic portable equipment, which has the maximum frequency of rotation of the rotor - 4000 revolutions per minute. The main purpose of the model is the fractional separation of liquid media with a density of 2 g/cm3 in the field of action of centrifugal forces Centrifuges are standard equipment in every laboratory and are intensively used to separate components of different densities. The device is suitable for glass and plastic tubes of various sizes, as well as vacuum containers of the vacutainer type.

Sample shredder (homogenizer).

Laboratory equipment that is used in the case, if the sample cannot be measured correctly without destroying it. It is used to grind the sample, mixing with the buffer medium and can significantly speed up the process of measuring the sample parameters.

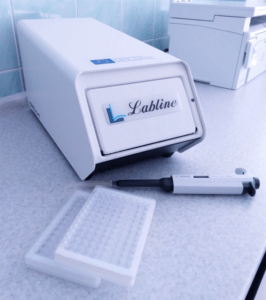

ELISA analyzer (ELISA).

The high-speed immunoenzyme analyzer is a photometric system, which is intended for reading and calculating the results of analyses. The device can be used in various fields: clinical diagnosis, environmental monitoring, monitoring of food products, immunodiagnostics and veterinary diagnostics. It provides the most reliable results in an extremely short period of time and at the same time it is possible to conduct an analysis 96 samples. In the last decade, there has been a rapid introduction into laboratory practice of immunoenzymatic methods for analyzing the quality and safety of food products, related to the improvement of the technique of such analysis and due to the need to conduct rapid, sensitive, specific, productive and simple methods.

Enzyme immunoassay (from English. Enzyme-linked immunosorbent assay, ELISA) – it's simple, a convenient and fast method for the detection of antibiotics, allergens, mycotoxins, pathogens, etc. The research is based on the specific interaction of antibodies and antigen. ELISA analysis – laboratory immunological method of qualitative or quantitative determination of various low molecular weight compounds, macromolecules, viruses, etc., which is based on a specific antigen-antibody reaction.

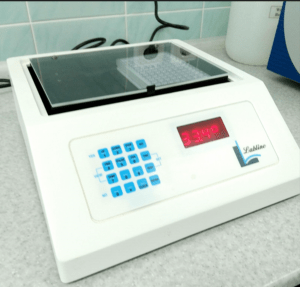

Shaker-incubator for ELISA tablets (Thermoshaker).

This is a laboratory device from the group of thermostatic equipment. The device is unique in that, which performs several procedures at the same time: it shakes and regulates the temperature of the tablets of the standard sample on 96 holes.

The device is usually used for mixing those substances in laboratory conditions, for which it is important to observe a certain temperature regime. The shaker-incubator extremely precisely fixes the temperature of the sample and keeps it at a certain level until the end of mixing. The incubation shaker is capable of heating the sample, and cool it to the desired temperature.

Automatic tablet washer.

The laboratory equipment is designed for washing 96-well tablets during ELISA analysis. It has three channels for washing solutions and one container for draining.

The eight-channel washing head allows you to wash the 96-well plate in any direction. The device is fully programmable, which ensures multi-stage ripening of the solution, aspiration (aspiration, a combination of aspiration/fluid dosing and soaking, as well as a soaking cycle over a period of time). Liquid dosing system for each channel separately.

Primo Star microscope.

Binocular with LED and halogen illuminator with. Universal microscope, which provides all operations, necessary in educational and laboratory practice. The Primo Star microscope is used to teach methods of phase-contrast diagnostics and other modern microscopy methods.

Densitometer DEN-1B

A device for determining the turbidity of bacterial suspensions. The device determines the concentration of cells in bacterial and microbiological suspensions, using the range from 0,3 to 5,0 McFarland units. The DEN-1 densitometer is effective in researching fermentation processes, sensitization of microorganisms to new antibiotics, as well as determination of bacterial strains in various test systems. in addition, the capabilities of the device allow you to measure the optical density of solutions at a fixed wavelength and carry out quantitative analysis of dissolved substances.

Ice cream maker

Manual ice cream maker DEX DICM – 100 for making sherbets, sorbets and various types of milk-based ice cream allows you to quickly and easily make a tasty and natural delicacy in half an hour. The ice cream maker has a compressor, which allows you to make ice cream at any convenient time quickly and easily. Sound signal “request” everyone to taste a delicious delicacy from childhood! The LED display shows the ambient temperature and the time until the end of cooking. The transparent lid will allow you to observe the cooking process.

Separator

The electric separator is designed to separate whole milk into cream and skimmed milk with simultaneous cleaning of impurities.. The manual separator is simple and reliable in operation. The quality of the finished product, obtained in separators, depends on pretreatment, from temperature (recommended 40-45 degrees) during separation, from the mass fraction of fat, milk thickness, from the degree of contamination of milk, as well as from the speed of rotation of the drum, etc. During separation, the chemical composition of substances does not change.

Vacuum evaporation unit

The vacuum evaporation unit is designed for thickening (concentration) milk. Condensed milk with sugar is included in the group of milk preserves. One of the methods of technological processing of milk in order to extend its shelf life is canning it by thickening it with sugar. The device also allows you to get concentrated juice, vegetable paste, including tomato, fruit and berry puree, sugar syrup, distilled water, canned meat and fish, medicinal plants, jam. The design is very convenient for plumbing, etc. To. collapsible. Can be served by one person.

Centrifuge

The OPN-8 desktop centrifuge is a batch centrifuge, is used to separate heterogeneous liquid systems in the field of centrifugal forces.

The centrifuge is intended for use in research, namely to determine the mass fraction of fat in dairy products, the amount of isolated serum, etc.

The department's laboratories are also equipped with such devices: sugar meter URL-5, photoelectrocalorimeter KFK-3, URL refractometers, universal ionometer EV-74, filtration plant, hairdresser, cheese bath, cauldron for melting cheese mass, electronic scales, thermostats, electric oven, microscopes, distiller, drying cabinets, pH meter and others.

The department is equipped with a mini-line for the production of drinking milk, fermented milk drinks, sour cream and sour milk cheese, pilot plants for the production of fermented milk drinks, solid, soft, fused, sour milk cheeses, condensed and dry canned milk, butter, products of the oil and fat industry.

The department has all the conditions for carrying out the educational process and research work of masters. The department has the necessary equipment and ingredients (leavening compositions of direct application of advanced European and Ukrainian manufacturers, lactating enzyme preparations, whey protein concentrates, grain additives - flour for children's and dietary purposes, vegetable oils, carbohydrate additives - lactulose concentrates, Jerusalem artichoke, etc) for the organization of production of dairy products, including. functional, health and special purposes. To control the quality of raw materials, semi-finished products and finished products, the course of technological processes at the department has the necessary devices.